Japan’s Strategic Move: Building a Rare‑Earth Supply Chain Independent of China

Japan has successfully diversified its rare-earth supply chain, reducing dependence on China by partnering with Australia and Malaysia, investing in recycling, and establishing strategic stockpiles. This strategy ensures stable access to minerals essential for EVs, electronics, and defense technologies, providing a blueprint for global supply-chain resilience

Japan, a global leader in technology and manufacturing, has made a significant strategic shift in securing rare‑earth minerals, aiming to reduce its historical dependency on China. Rare earths—critical for producing high-performance magnets used in electric vehicles (EVs), smartphones, wind turbines, and defense technology—were once almost exclusively imported from China, which controls around 60–70% of global rare-earth production.

The urgency for diversification became acute in 2010, when China temporarily restricted rare-earth exports to Japan during a diplomatic dispute over the Senkaku/Diaoyu Islands. At the time, Japan imported nearly 90% of its rare-earth supply from China, highlighting the vulnerability of its industrial sector to geopolitical tensions.

In response, Japan pursued a multi-pronged approach:

Diversifying sourcing—partnering with foreign suppliers such as Lynas Rare Earths in Australia, which mines rare-earth ore at Mount Weld, one of the richest deposits in the world. The ore is then processed at Lynas’s facility in Kuantan, Malaysia, before shipment to Japan.

Government-backed initiatives — Through JOGMEC (Japan Oil, Gas and Metals National Corporation), the government provided funding, technical support, and long-term contracts to secure a stable supply from multiple countries, including Australia, the United States, and Southeast Asian nations.

Domestic processing and recycling—Japan has invested in recycling rare-earth elements from used electronics and magnets, creating a circular supply chain that reduces reliance on imports.

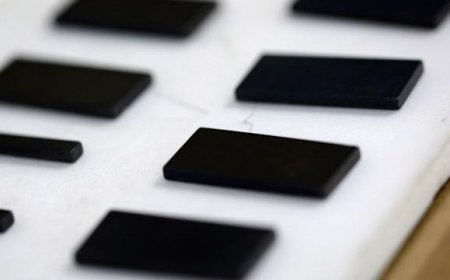

Strategic stockpiling—establishing reserves of heavy rare-earth elements like dysprosium and terbium, which are essential for high-temperature-resistant magnets in EV motors and military equipment.

This diversified approach has already borne fruit. Japan’s dependence on Chinese rare earths has fallen from nearly 90% in the early 2010s to roughly 60–70% today, with plans to further reduce it to below 50% by the late 2020s.

The Japanese model offers valuable lessons for other countries grappling with the concentration of rare-earth production in China. By combining diversified sourcing, international partnerships, domestic processing, and strategic stockpiling, Japan has strengthened its industrial resilience while safeguarding its high-tech and defense sectors. Experts say this approach will be critical as global demand for electric vehicles, renewable energy technologies, and electronics continues to surge.

In addition, Japan has been actively collaborating with the United States and Australia under trilateral frameworks to create a secure, environmentally sustainable supply chain for rare-earth minerals. These collaborations aim not only to reduce dependency on China but also to ensure geopolitical stability and reliable access to critical resources in an era of growing global competition.

With rare-earth demand expected to grow exponentially in the coming decade, Japan’s strategy underscores the importance of foresight, diplomacy, and innovation in securing strategic industrial resources.

What's Your Reaction?

Like

0

Like

0

Dislike

0

Dislike

0

Love

0

Love

0

Funny

0

Funny

0

Angry

0

Angry

0

Sad

0

Sad

0

Wow

0

Wow

0